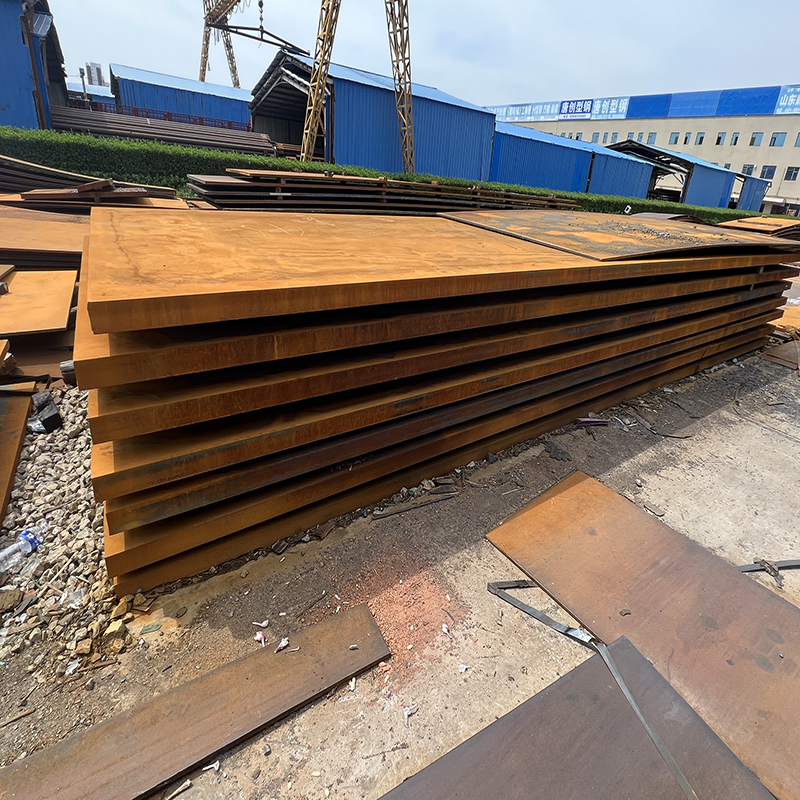

Nxiba ipleyiti yentsimbi enganyangekiyo

ITekhnoloji yoLungiso

Ukunxiba ipleyiti yentsimbi ekwaziyo ukumelana nentsimbi yenziwe ngentsimbi ephantsi kwekhabhoni kunye ne-alloy ekwaziyo ukumelana nomgangatho.Umaleko we-alloy ongagugiyo ngokuqhelekileyo yi-1 / 3 ~ 1 / 2 yobukhulu obupheleleyo.Ngexesha lokusebenza, i-matrix ibonelela ngeempawu ezibanzi njengamandla, ukuqina kunye neplastikhi ukuxhathisa amandla angaphandle, kunye ne-alloy wear-resistant layer ibonelela ngeempawu zokunxiba ezihlangabezana neemfuno zeemeko zokusebenza ezichaziweyo.

Ipleyiti yentsimbi engagungqiyo idityaniswe ngesinyithi phakathi kwe-alloy enganyangekiyo yomaleko kunye ne-substrate.Ngezixhobo ezikhethekileyo kunye nenkqubo ye-welding ezenzekelayo, i-high hardness self-self-protective ialloy welding wire idityaniswe ngokulinganayo kwi-substrate.Inani leeleya ezidityanisiweyo ngomnye ukuya kwisibini okanye nokuba zininzi.Ngexesha lenkqubo edibeneyo, iintanda ezinqamlezileyo ezifanayo zivela ngenxa yomlinganiselo ohlukeneyo we-alloy shrinkage ratio, eyona nto iphawulekayo yepleyiti yensimbi engaguqukiyo.

I-alloy wear-resistant layer iqulunqwe kakhulu yi-chromium alloy, kunye nezinye izinto ze-alloy ezifana ne-manganese, i-molybdenum, i-niobium kunye ne-nickel nazo zongezwa.I-carbides kwisakhiwo se-metallographic isasazwa kwi-fiber shape, kwaye i-fiber direction ye-fiber i-perpendicular kumphezulu.Ubulukhuni obuncinci be-carbide bunokufikelela ngaphezulu kwe-hv1700-2000 kwaye ubunzima bomhlaba bunokufikelela kwi-HRC58-62.I-alloy carbides inozinzo olomeleleyo kubushushu obuphezulu, igcina ubulukhuni obuphezulu, kwaye inokumelana ne-oxidation elungileyo.Zingasetyenziswa ngokuqhelekileyo ngaphakathi kwe-500 ℃.

Uluhlu olungagungqiyo luthatha uhlobo lomsele omncinci (2.5-3.5mm), umjelo obanzi (8-12mm), i-curve (s, w), njl;Ikakhulu yenziwe ngealloyi yechromium kunye namanye amacandelo ealloy anjenge manganese, molybdenum, niobium, nickel kunye neboron.I-carbides kwisakhiwo se-metallographic isasazwa kwi-fiber shape, kwaye i-fiber direction ye-fiber i-perpendicular kumphezulu.Umxholo we-carbide ngu-40-60%, i-microhardness inokufikelela ngaphezu kwe-hv1700, kwaye ubunzima bomhlaba bunokufikelela kwi-HRC58-62.

Ubungakanani besicelo

Nxiba ipleyiti yentsimbi exhathisayo inokumelana nokunxiba okuphezulu kunye nokusebenza kakuhle kwempembelelo.Inokunqunyulwa, igobe kwaye idibanise.Inokudibaniswa kunye nezinye izakhiwo nge-welding, i-plug welding kunye ne-bolt connection.Igcina ixesha kwaye ifanelekile kwinkqubo yokugcinwa.Isetyenziswa ngokubanzi kwi-metallurgy, amalahle, isamente, amandla ombane, iglasi, imigodi, izinto zokwakha, izitena kunye neethayile kunye namanye amashishini.Xa kuthelekiswa nezinye izinto, ineendleko eziphezulu zokusebenza, iye yathandwa ngamashishini amaninzi kunye nabavelisi.